Bearing Lubrication Monitoring with Ultrasound

قطاع الخدمات

الأنشطة التجارية والشركات

وصف المنتج

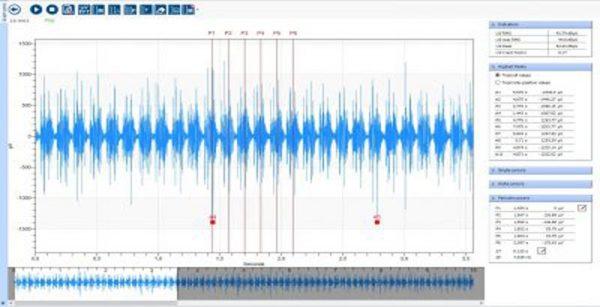

Bearing Lubrication Monitoring with Ultrasound;

Why we Lubricate Bearings For 4000 years we have been lubricating our machinery and rotating assets to increase their efficiency, reliability and lifespan. Proper bearing lubrication minimizes the surface contact of machinery, reducing undesired friction, excessive heat, metal-on-metal contact and wear and tear. Lubrication not only protects ball and roller-element bearings from themselves by reducing friction but also from corrosion and the elements. Grease is the lubrication of choice within the industry, as it is easy to apply and it provides the bearing housing with a protective seal from the elements. For a procedure proven reliable for the past 4 millennia, it is surprising to hear so many premature bearing failures are lubrication-related. Improper lube selection, amount, intervals as well as lubricant contamination and degradation are to blame.

مناطق التجارة

Copyright Netetrade 2025. Developed by Yartu Labs