Conveyor belts

Transport und Logistik

Versand und Logistik

Produktbeschreibung

Conveyor belts;

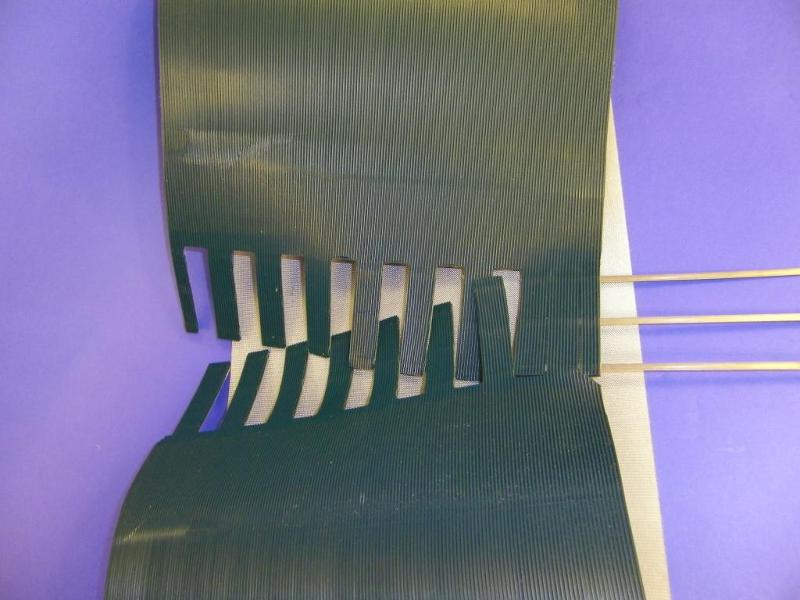

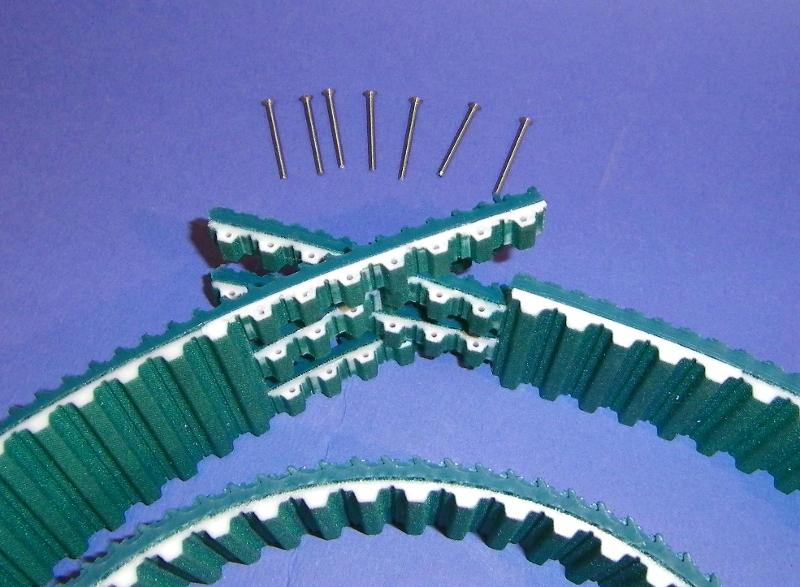

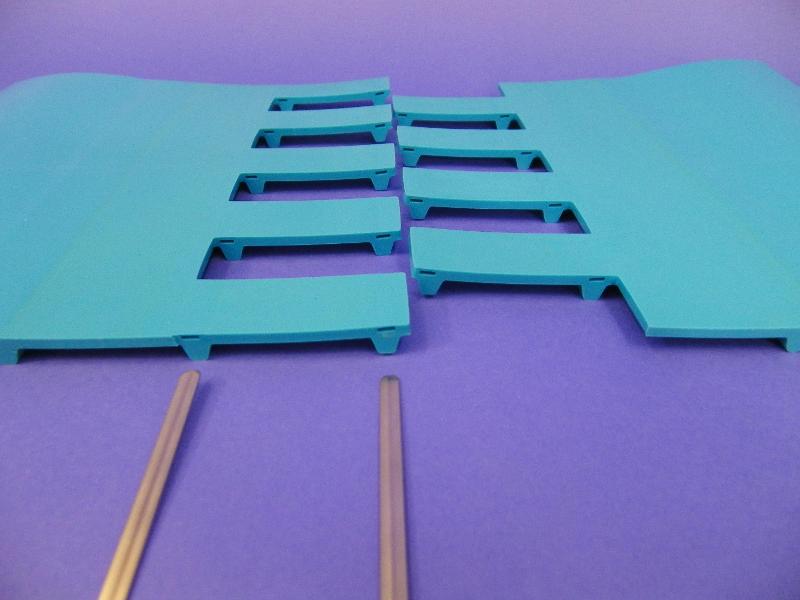

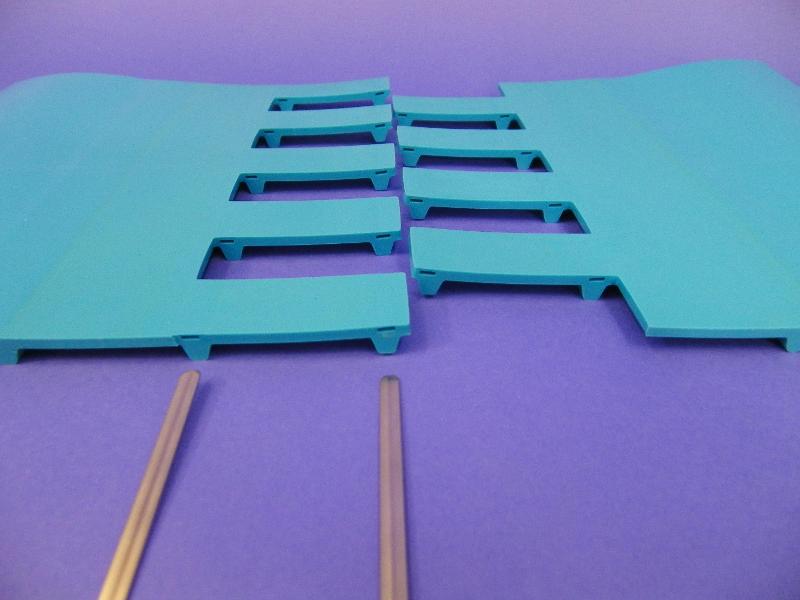

The mechanical fastening system ERO Joint® is available in conveyor belts with a thickness over 1mm. The assembly is made by threading of 3 transversal pins (stainless steel or polyacetal pins can be used). ERO Joint® splice is integrated into the conveyor belt, with no structural, width and colour changes. Tensile Kevlar cord can be embedded in Polyurethane upon request. Anyway using ERO Joint® conveyor belts ensure you a complete freedom and a high-flexibility: no specific tool, no splicing and welding procedure to respect, no deburring, no risk to miss the welding. ERO Joint® conveyor belts are easy to assemble. ADVANTAGES Advantages are a fast and easy installation and assembly. With this new solution of mechanical fastening system, you will save time and optimize your production downtime by reducing the repair time. The mechanical joint system ERO Joint® keeps the minimal diameter of the belt and is compatible with conveyor belts scrapers. Mechanical fastening systems ERO Joint® are lasting solutions. The ERO Joint® splice shape may be adapted in order to increase the mechanical resistance. The ERO Joint® conveyor belts are spliced in our production using a patented process and fitted with the length requested. Alternatives Fastening solution A conveyor belt may be assembled with plastic hinge fasteners but whatever the way of lacing technology, conveyor belts with mechanical system ERO joint® will have a longer lifespan. The mechanical joint fastening systems ERO Joint® keep the thickness and the structure of belt on the top surface. The ERO Joint® splicing system limits also the microbial growth compared with fasteners. PosiLace™ lacing solution The mechanical joint fastening systems ERO Joint® keep the thickness and the structure of belt on the top surface. Compared with the ERO Joint®, the PosiLace™ splice is not compatible with scrapers. Furthermore, the ERO Joint® eliminates belt stretch in the splice zone. Welding on site Conveyor belts may be welded on site by using a hot press in accordance with the splicing and welding procedure. For that, you need to buy a hot press or pay a maintenance intervention. This type of intervention takes at least 3 hours. The conveyor belts with mechanical fastening system ERO joint® are assembled in 15 minutes. Thanks to this new lacing technology, production costs are significantly reduce and the downtime too.

Handelsbereiche

Telefon:

Email:

Die Unterstützung

Copyright Netetrade 2025. Developed by Yartu Labs