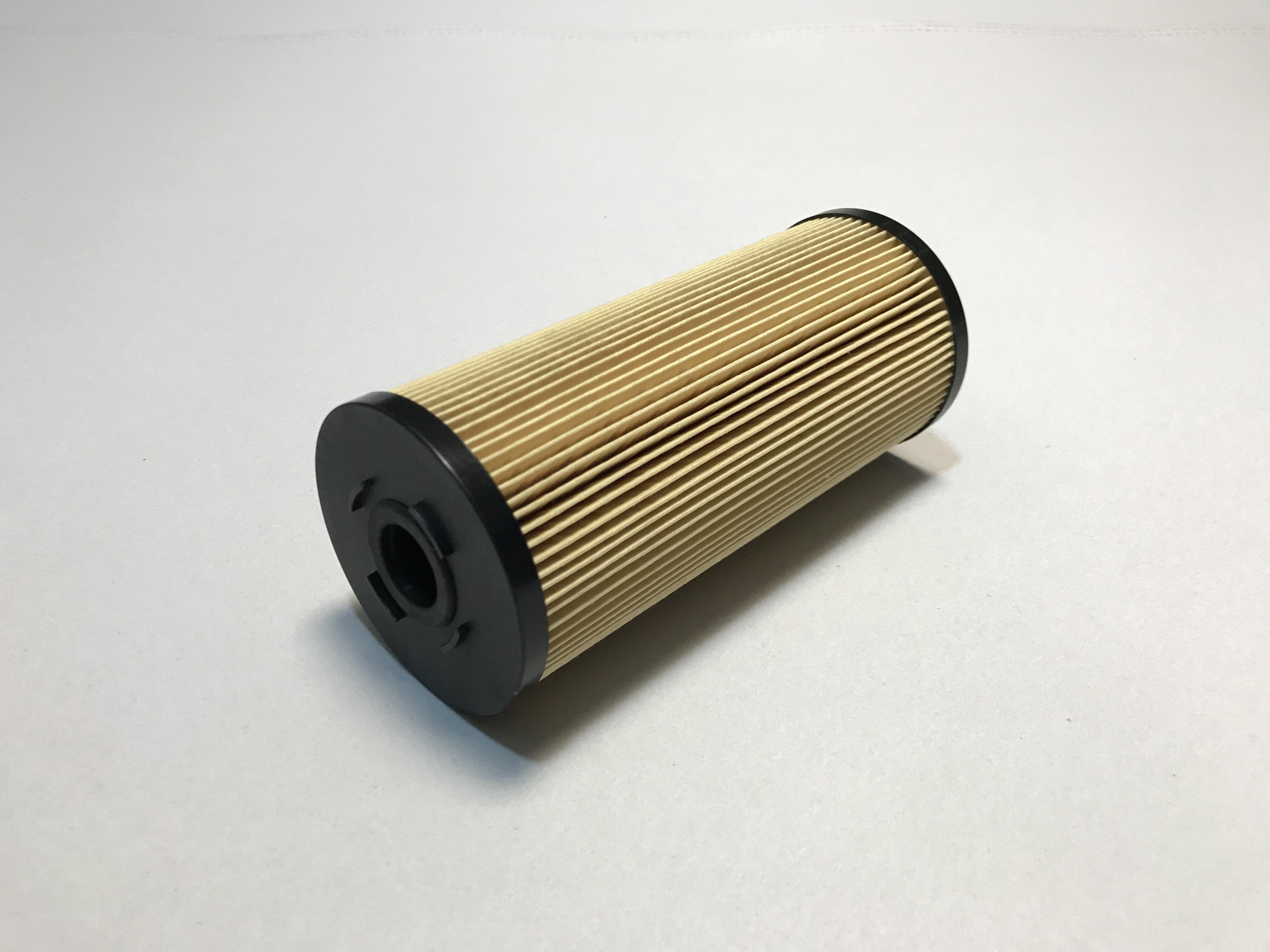

Composites

Chimie, médecine et médical

Combustibles pétroliers et additifs

Chimie, médecine et médical

Peinture et groupe industriel

Description du produit

Composites;

PU composites are mainly found in the production of moulded parts resistant to bending. The skilful combination of materials puts the topic of lightweight construction into the spotlight (honeycomb technology applications). Sophisticated surface designs are supported by corresponding PU / UP resin systems. Thanks to the reduced component weight, moulded part applications are used in the automotive sector – and, with corresponding flame protection formulations, also in rail vehicle construction. Typical properties Moulded part density of 450–1100 kg/m³ Fibre proportion from 30 % Available foaming agents: usually water Reinforcing materials Glass fibre rovings Glass fibre mats and non-crimp glass fibre fabrics Carbon fibres Natural fibres (hemp, sisal, coconut etc.) Special formulations and versions Honeycomb materials for sandwich structure components Paper honeycombs Waterproof paper honeycombs (patent-pending process) Plastic honeycombs Aluminium honeycombs Systems with a large processing window Use of polyols based on renewable resources Self-parting with simultaneous good lamination properties Flame protection formulations Automotive: FMVSS 302 Rail vehicle construction: DIN 5510 (S4, SR2, ST2) Aircraft construction: FAR 25853, ABD 0031 Construction industry: DIN 4102 B2

Zones commerciales

Des produits

DE

Chimie, médecine et médical, Combustibles pétroliers et additifs, Chimie, médecine et médical, Peinture et groupe industriel

DE

Chimie, médecine et médical, Combustibles pétroliers et additifs, Chimie, médecine et médical, Peinture et groupe industriel

DE

Chimie, médecine et médical, Combustibles pétroliers et additifs, Chimie, médecine et médical, Peinture et groupe industriel

DE

Chimie, médecine et médical, Combustibles pétroliers et additifs, Chimie, médecine et médical, Peinture et groupe industriel

Copyright Netetrade 2025. Developed by Yartu Labs