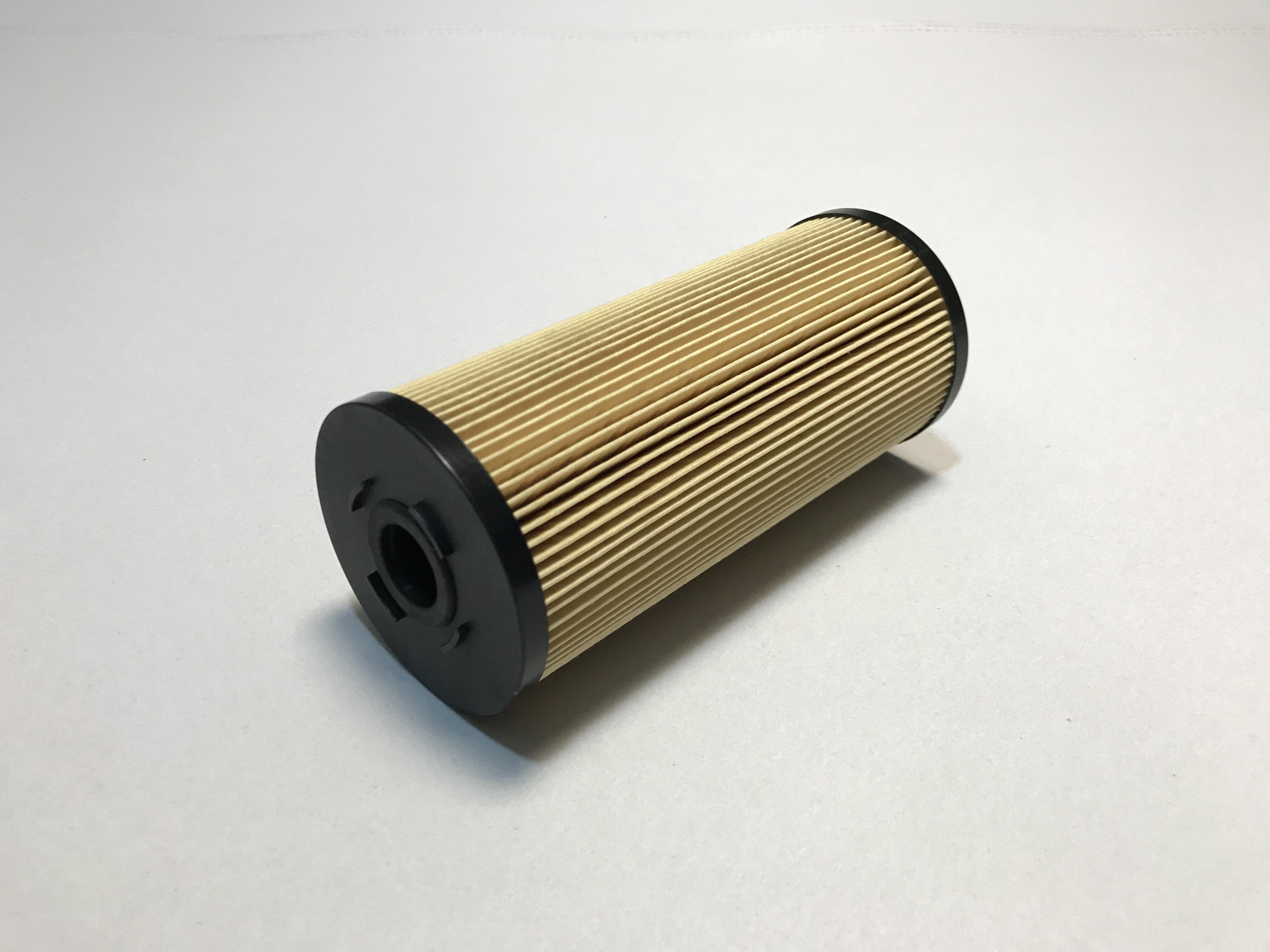

Sintering for Shock absorbers production

Transport et logistique

Expédition et logistique

Description du produit

Sintering for Shock absorbers production;

Currently, production of the parts from mixed metallic powders is slowly displacing traditional casting and stamping. It is happening because this method is different with its speed and cost efficiency. Wastes from the metal-parts production can be used to produce powders. Parts, produced by this method, have high durability and wear-resistance. Sintering allows to receive parts with precise geometric forms. Parts don’t require further machining. Technology of production of sintering suggests putting metal powders into special forms. They are thermal treated in the gas environment, that allows to increase plasticity of material and also add special polymers. Then, parts are being pressed, rolled and formed. During those processes, parts of the metal powders are strongly melted with each other, creating a monolith mass. In order to provide parts with hardness and wear-resistance, they are being thermal treated in special furnaces. More info https://eurobalt.

Zones commerciales

Des produits

EE

Transport et logistique, Expédition et logistique

EE

Transport et logistique, Expédition et logistique

EE

Transport et logistique, Expédition et logistique

EE

Transport et logistique, Expédition et logistique

Copyright Netetrade 2025. Developed by Yartu Labs