Production

Processamento metalúrgico e metal

Fio, cabo, parafuso e porca

Descrição do produto

Production;

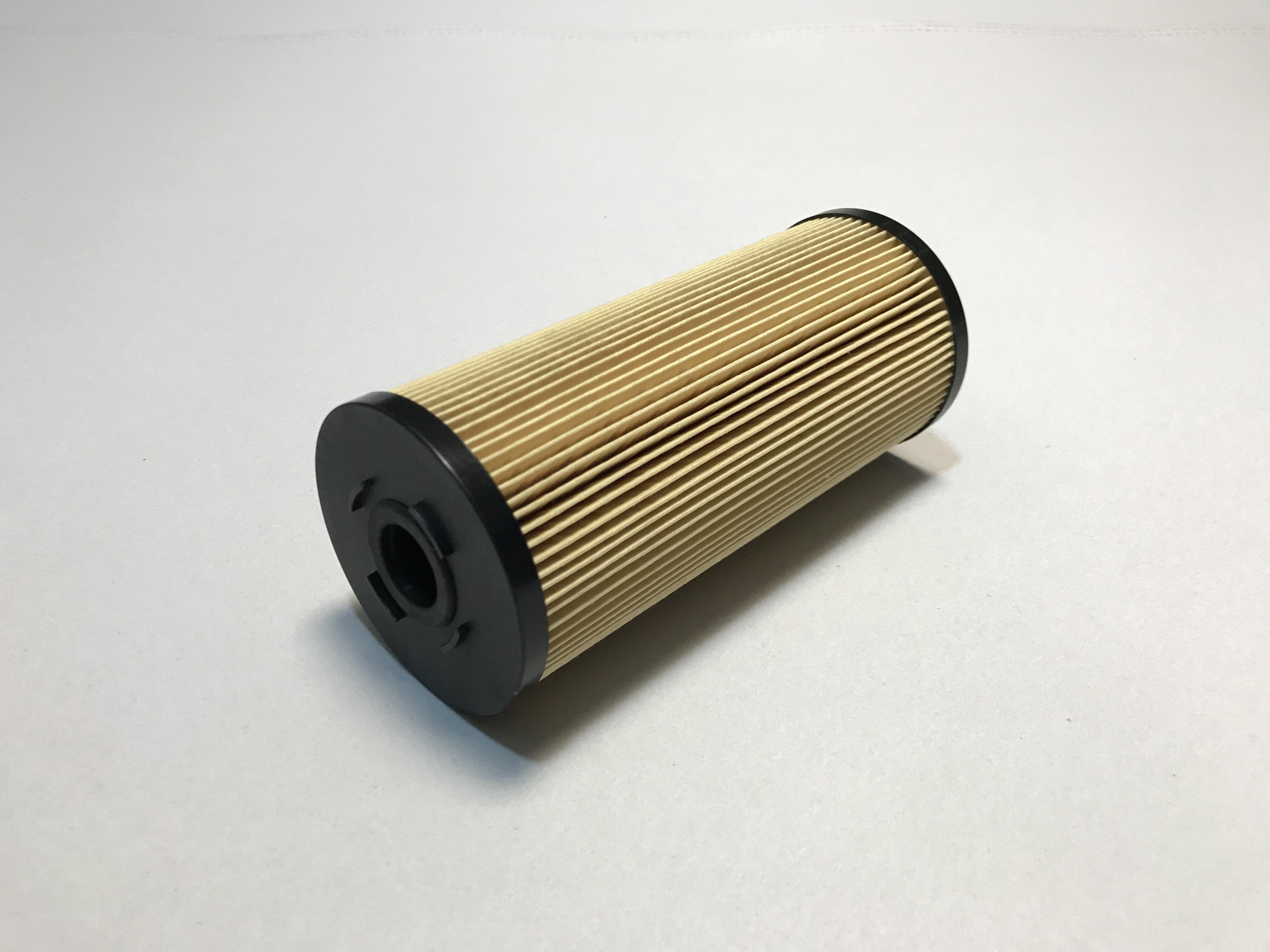

You can hear the efficiency. Large forces are involved in each pressing operation in the production facility. Only in this way can the materials be formed when cold. Thus, within a very short period of time, wire becomes a cold-formed part. Rapid, successive knocks - that is the "sound" of the production facilities. You can hear speed and precision. OBO keeps control of all the steps. This starts with tool development according to our specifications. The tools are manufactured by renowned manufacturers. The finished tools are then used in the presses and rollers of our production facility. Forming may be followed by a hardening process or surface coating. Well packed, it then goes off to dispatch and to the address required by the customer. Thanks to this closed production process on our premises and with our partners, we can guarantee the highest level of quality in every work step. Presses A total of 20 pressing machines are used in OBTEC's product facility. They range from...

Áreas comerciais

Telefone:

O email:

Apoiar

Copyright Netetrade 2025. Developed by Yartu Labs