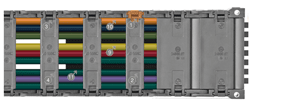

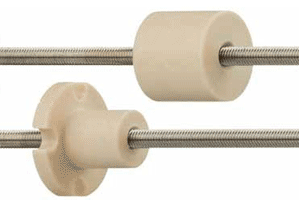

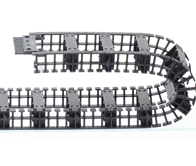

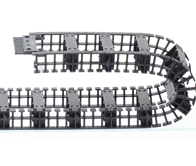

System T3 highly flexible, lowvibration profile chain T3.29

Metalurji ve metal işleme

Metal Mamüller

Ürün/Hizmet Açıklaması

System T3 highly flexible, lowvibration profile chain T3.29;

T3 System combines low-noise operation, low sound level, simple installation and cost effectiveness. The side plates that can be plugged into each other replace the conventional pin/hole connection and prevent relative movements between the joints. For this reason, an almost complete freedom from wear is attained (clean room). The geometry of the T profile ensures that almost no polygon effect is generated during the filling of the E-Chain®. The T band operates very harmoniously and round, and has extremely low vibration and noise In order to reduce the manufacturing and assembly costs, the T-profile is mounted not individually, but - similar to the igus® E3 System - in a length of 8 chain links. Due to its low weight the igus® T-Band is suitable for applications with rather low fill weights and short strokes, combined with high accelerations and speeds. Extremely low noise - System T3 tests in the igus® lab showed at 1 m measuring intervals: a value of ≈ 33 dB(A) at 26.5 dB(A) basic sound level for Series T3.29.050.038 T3.29 Inner height hi: 29 mm Inner widths Bi: 30 - 120 mm bending radii R: 38 mm Pitch: 15 mm E-Chain® T3.29 Inner height hi: 29 mm Inner widths Bi: 30 - 120 mm bending radii R: 38 mm Pitch: 15 mm E-Chain® IPA classification - Report IG1303-640-1: ISO Class 2, according to DIN EN ISO 14644-1 for system T3, Series T3.29.050.038.0 at v = 0,5 m/s, 1 m/s, 2 m/s System T3: e-chain® band for highly dynamic applications When developing the 3-part, T-shaped "T3" profile chain, the emphasis was on low running noise. At the same time the T3 profile chain was supposed to be particularly cost-effective. This was achieved through the side-plate bands consisting of 8 chain links in one piece, as well as the option of using components from the popular E6 construction kit. The T3 profile chain is particularly flexible and runs in a round shape due to the special shape of the site plates. As there is no need for a pin/hole connection, the T3 profile chain also features particularly low abrasion and hence can also be used in clean room applications. Extremely low noise and low vibration Cost-effective e-chain® for simple applications For high speeds and acceleration Light-weight Minimal abrasion For short strokes Accessories: Separators, strain reliefs, mounting brackets Typical industries and applications Printers and plotters Cleanroom application Production and processing of semiconductors Optics Automatic insertion machines Measuring technology E-Chain® selection aids You can find the right E-Chain® quickly by entering concrete parameters and with the aid of a comparison table. Selection aids Assembly instruction Joining the E-Chain®. Assembly instruction

Ticaret alanları

Ürünler

DE

Metalurji ve metal işleme, Metal Mamüller

DE

Metalurji ve metal işleme, Metal Mamüller

Telefon:

E-posta:

Destek

Copyright Netetrade 2025. Developed by Yartu Labs