Flat Belt

Transport und Logistik

Versand und Logistik

Produktbeschreibung

Flat Belt;

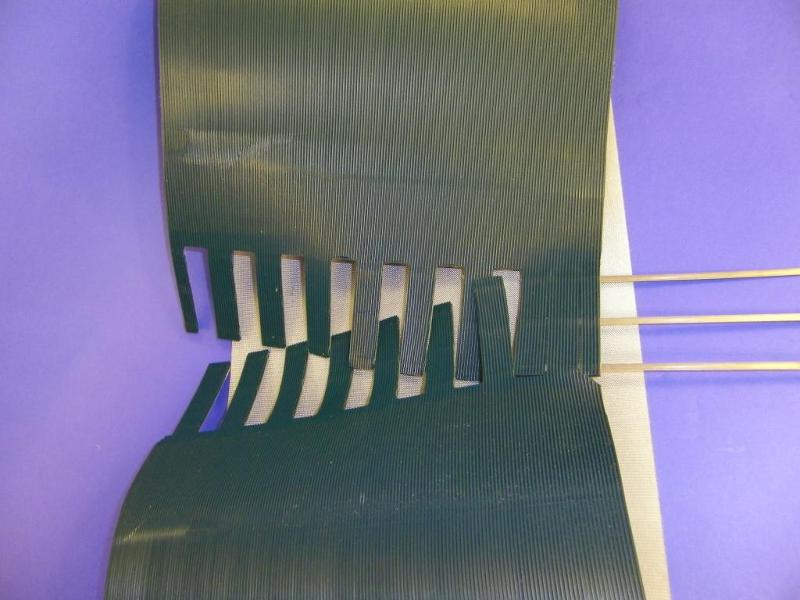

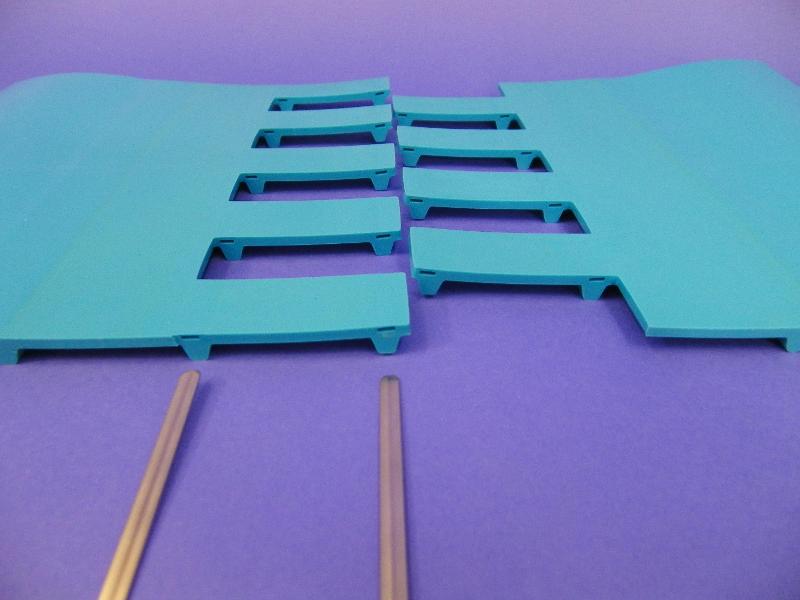

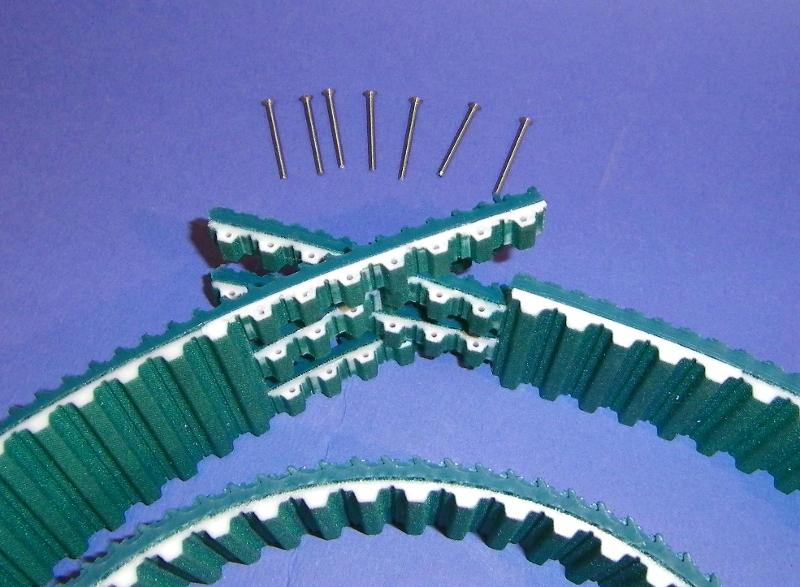

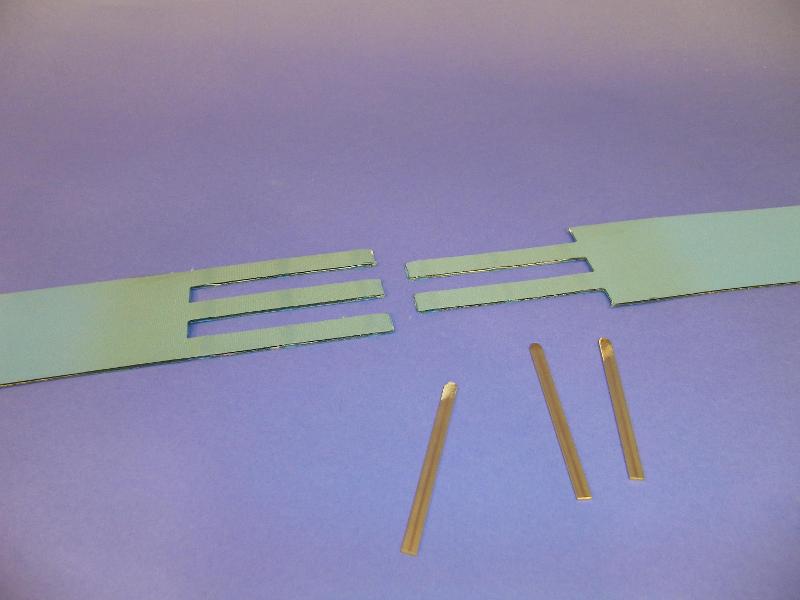

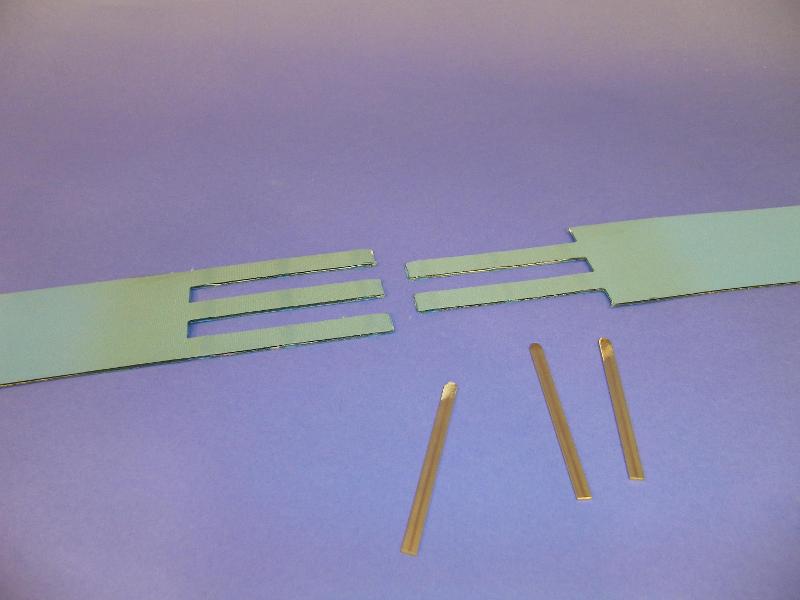

The mechanical fastening system ERO Joint® is available in flat belts with a thickness over 1mm containing an intermediate layer of Polyurethane. The assembly is made by threading of 3 transversal pins. Anyway using ERO Joint® flat belts ensure you a complete freedom and a high-flexibility: no specific tool, no splicing and welding procedure to respect, no deburring, no risk to miss the welding. ERO Joint® flat belts are easy to assemble. Advantages are a fast and easy installation and assembly. With this new lacing technology, you will save time and optimize your production downtime by reducing the repair time. The ERO Joint® flat transmission belts cannot be use on every installation (high speed or small diameter of pulley). This is short-term solution to repair and restart quickly your production. The lifespan is lower compared to welded belts. The ERO Joint® splice shape may be adapted in order to increase the mechanical resistance. The ERO Joint® flat belts are spliced in our production using a patented process and fitted with the length requested. Alternatives Lacing solution A flat belt may be assembled with hinge fasteners but whatever the way of lacing technology, conveyor belts with mechanical system ERO joint® will have a longer lifespan. The mechanical joint fastening systems ERO Joint® keep the thickness and the structure of belt on the top surface. Welding and gluing on site Flat belts may be welded or glued on site by using a hot press in accordance with the splicing and welding procedure. For that, you need to buy a hot press or pay a maintenance intervention. This type of intervention takes time. The flat belts with mechanical fastening system ERO joint® are assembled in 5 minutes. Thanks to this new lacing technology, production costs are significantly reduce and the downtime too.

Handelsbereiche

Telefon:

Email:

Die Unterstützung

Copyright Netetrade 2025. Developed by Yartu Labs