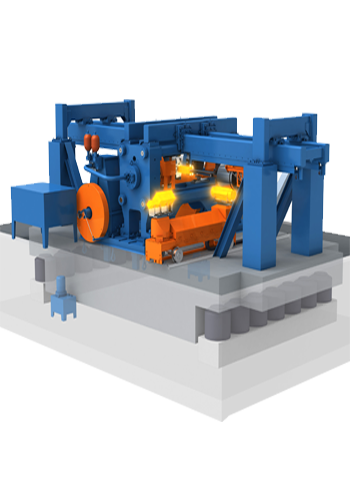

Forged Roller / Cross Wedge Rolling Mill RCW / QKW

Product Description

Forged Roller / Cross Wedge Rolling Mill RCW / QKW;

Forged roller / cross wedge roller RCW / QKW Forged Roll RCW: The forged roll is designed for pre-forming round and square material. The billet is fed radially to the cylinders by a manipulator and pre-formed in the individual sectors (transitions). Special features of RCW: Custom forged roll manipulator LASCO manipulator holder with compensating element offset changes in file lengths Direction perception (synchronized or reverse rotation) can be changed by direct drives Optional cylinder temperature control (heating / cooling) Cross wedge roller QKW: The cross wedge roller is used in front and final shaping of round forged parts (material distribution), as well as in hollow shafts gradually. The heated round bars are rolled between two synchronized rollers equipped with tools. Special features of QKW: The roller clearance can be adjusted symmetrically to the rolling plane Direction perception (synchronized or reverse rotation) can be changed by direct drives Optional cylinder temperature control (heating / cooling) Optional cylinder change manipulator Advantages of RCW and QKW: No impeller, clutch or brake required due to torque motor drive High dynamics and control accuracy through the drive via two electronically synchronized servo torque motors Electronic pulley synchronization optimizes the dimensioning of the cylinder play and allows adjustment of the cylinder play during the rolling process Significant material savings Optimized workpiece surfaces with non-ferrous metals Patented roll changing system Dimensions: Cylinder diameters from 350 mm to 1,400 mm (QKW) and 460 mm to 930 mm (RCW) Please review our catalog about our machine and watch our video

Trade Areas

Phone:

E-Mail:

Support

Copyright Netetrade 2025. Developed by Yartu Labs