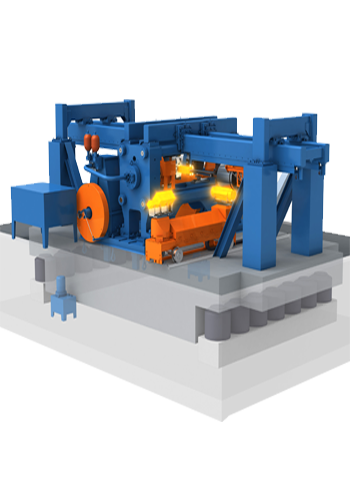

Electric shrinkage, blow molding welding

Product Description

Electric shrinkage, blow molding welding;

Electrical shrinkage combines the heating and collection of bar material in a single process. The technological limitations of other forming methods can be overcome in part by electrical contraction. In valve production, for example, the ratio of sad length and bar diameter can be increased up to a factor of 20: 1. LASCO offers special designs as well as horizontal (EH) and vertical (EV) electrical receivers. They can be combined with handling systems and suitable end forging equipment to create efficient fully automated production lines. Special features: Servo drive and CNC control for actuating cylinder and anvil plate Free programming of heating current as well as heating and withdrawal rate during stroke Limit switches do not need to be set or stopped Permanent temperature control of the flushing head Automatic log control Automatic loading, unloading and transport devices Basic not required Efficient programmable control system with modem for operator guidance, product data management and remote diagnostics Can be operated in manual and fully automatic mode Capacities: Powers starting from 2,500 - 10,000 kN

Trade Areas

Phone:

E-Mail:

Support

Copyright Netetrade 2025. Developed by Yartu Labs